该缆绳是由超高分子量聚乙烯纤维和尼龙单丝制造,是由各六个分别是“S”和“Z”捻向的绳股空心编织而成,让绳子不会发生旋转,特点是耐磨,比其他缆绳增加了两到三倍的耐磨性。...

高分子量聚乙烯纤维和尼龙单丝耐磨复合缆绳

High Molecular Weight Polyethylene Fiber And Nylon Monofilament Wear Mixed Rope

一、描述Description

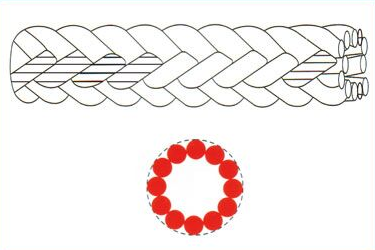

该缆绳是由超高分子量聚乙烯纤维和尼龙单丝制造,是由各六个分别是“S”和“Z”捻向的绳股空心编织而成,让绳子不会发生旋转,特点是耐磨,比其他缆绳增加了两到三倍的耐磨性。

This rope is made by the ultra-high molecular weight polyethylene fiber and nylon monofilament,It’s woven by separate six“S”and“Z”stands,Let the rope will not occur rotating, Its characteristic is wear-resisting,It increased two to three times the wear resistance than other ropes.

二、性能Performance

1)材料:高分子量聚乙烯纤维和尼龙单丝 Material: ultra-high molecular weight polyethylene(UHMWPE) and nylon monofilament

2)结构:八、十二股编织 Construction:8、12 strand braided

3)颜色:黄色,其他颜色 Standard color:Yellow, other colours:red,blue,green,orange and so on

4)比重:0.975浮水 Approx.Spec.Density:0.975 Floating

5)熔点:145°C~215°C Melting Point: 145°C~215°C

6)耐磨性:非常好 Vabrasion Resistance:Excellent

7)抗紫外线:好 U.V.resistance:Good

8)抗化学腐蚀性:非常好 Chemical corrosion resistance: Excellent

9)使用环境:最大70°C Temperature resistance: 70°C max continuous

10)每卷长度:220m Coil length: 220m

11)结强力损失:±10% Spliced strength: ±10%

12)重量和长度误差:±5% Weight and length tolerance: ±5%

13)吸水率:无 Water absorption:None

14)超高强:同等直径时,强度和钢缆相同 Stronger:under the same diameter,the strength is the same as the wire rope

15)应用范围:海洋工程、系泊、港口拖带、海军装备、国防军队装备、航天航空、电力通讯、大型精密物件吊装、体育器材等 Application:offshore,mooring,port towing, naval equipment, military equipment,aerospace, electrical communication,large precision object sling,sports equipment,etc.

三、参数表Parameter Table

|

直径DIA |

周长CIR |

重量Weight |

破断强力 |

||

|

MM |

INCH |

INCH |

KGS/100M |

LBS/100FT |

Breaking Strength |

|

28 |

1-1/8 |

3-1/2 |

50 |

33 |

45.5 |

|

30 |

1-3/16 |

3-3/4 |

58 |

38 |

52.6 |

|

32 |

1-1/4 |

4 |

66 |

44 |

60.8 |

|

34 |

1-11/32 |

4-1/4 |

74 |

49 |

68 |

|

36 |

1-7/16 |

4-1/2 |

84 |

56 |

75.4 |

|

38 |

1-1/2 |

4-3/4 |

93 |

62 |

83.4 |

|

40 |

1-19/32 |

5 |

103 |

68 |

94.6 |

|

44 |

1-21/32 |

5-1/4 |

126 |

83 |

110 |

|

48 |

1-7/8 |

6 |

150 |

99 |

130 |

|

52 |

2-1/16 |

6-1/2 |

176 |

116 |

148 |

|

56 |

2-1/4 |

7 |

203 |

134 |

160 |

|

60 |

2-3/8 |

7-1/2 |

233 |

154 |

180 |

|

64 |

2-1/2 |

8 |

264 |

174 |

208 |

|

68 |

2-11/16 |

8-1/2 |

297 |

196 |

230 |

|

72 |

2-7/8 |

9 |

338 |

223 |

265 |

|

76 |

3 |

9-3/8 |

374 |

247 |

305 |

|

80 |

3-5/32 |

10 |

413 |

273 |

340 |

|

88 |

3-7/16 |

11 |

495 |

327 |

410 |

|

96 |

3-13/16 |

12 |

583 |

385 |

500 |